Incredibly resilient to wear, a PCD (polycrystalline diamond) lathe insert is a cutting tool formed through incredibly high temperatures and pressures, fusing together diamond powder with a cobalt or other binder. Crafted for optimum toughness, these inserts are ideal for machining particularly hard materials on lathes or other machine tools.

PCD inserts can be employed to cut metals such as aluminum, brass, bronze, cast iron, steel, and titanium with ease; these inserts are also quite capable when it comes to machining non-ferrous metals, composites, plastics, and other non-metallic materials.

Different shapes including squares, rectangles, circles, and triangles are offered in PCD inserts. Grades within the PCD range are based on the size and form of the diamond particles, with higher grades defined by more refined diamond particles that bring greater wear resistance.

A screw or alternative securing device is used to fasten the PCD insert to the lathe tool holder. This ensures that the insert can withstand the force of the rotating tool like a drill bit or end mill, and can safely be machined.

The remarkable resilience of PCD inserts renders them applicable for numerous machining techniques, such as turning, boring, milling, drilling, grinding, and polishing.

Different companies offer PCD inserts, from the well-known Kennametal and Sandvik, to Mitsubishi and Sumitomo.

When compared to other lathe inserts, PCD inserts usually come with a higher price tag. But they possess a plethora of perks, such as an extended operation life, a faster cutting pace, and an improved surface finish.

Related Product

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

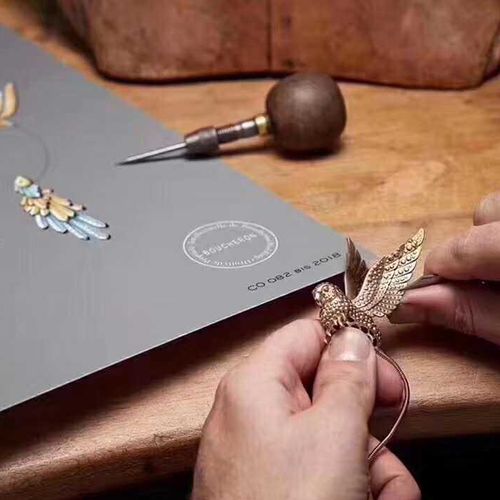

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

Post time: 2023-07-04