Welcome To MSK

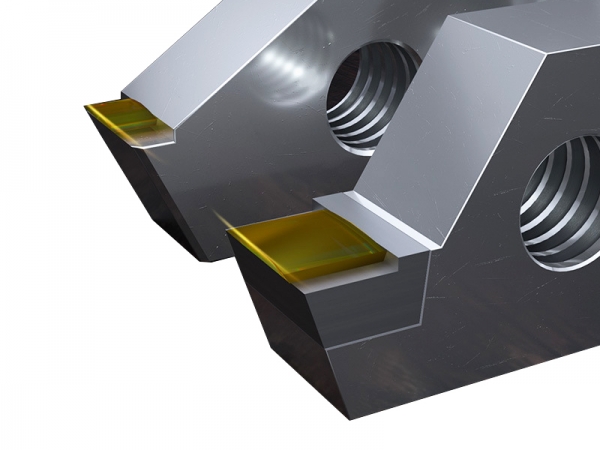

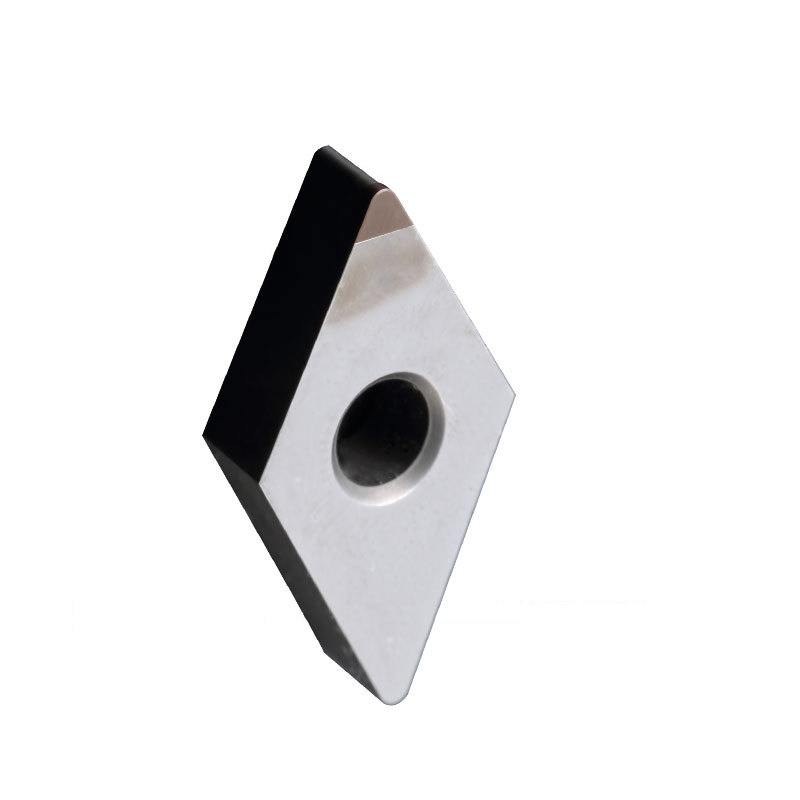

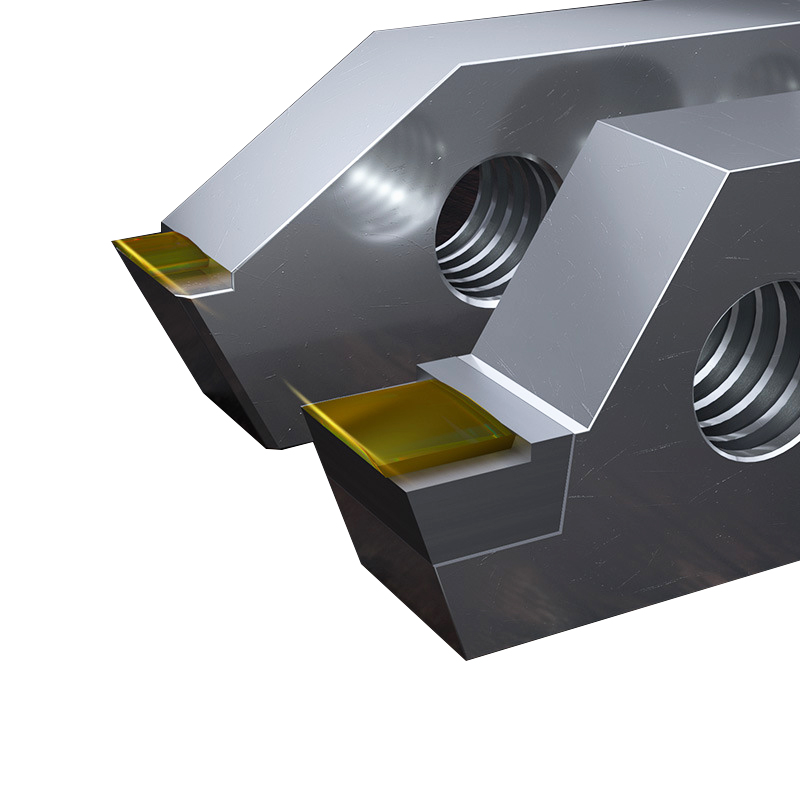

Single Crystal Diamond Polishing Cutter

| Origin | Tianjing, China | Shank Diameter | 6 (mm) |

| Brand | MSK | Blade Change Method | The Diamond Is Welded To The Cutter Body As A Whole |

| Material | Single Crystal Diamond (MCD) | Scope Of application | Acrylic, PVC, PC, ABS Plastic |

| Full Length | 34 (mm) | Specification | 34*12*6*R10 |

| per kit | 1 | Processing Effect | Processed Acrylic Surface Mirror Transparent |

| Product Name | Single Crystal Diamond Polishing Cutter | Brand | MSK |

| Wear-Resistant | 3-4 Times Harder Than Tungsten Steel | Life | Up To 50-100 times |

| Hardness | Around HV6000 | Material | Diamond |

| Processing Material | Graphite, Ceramics, Tungsten Steel, Acrylic Sheet, Silicon Carbide, Plastic, Copper-Aluminum Alloy | ||

feature:

- Single crystal diamond fine polishing knife, with fast processing efficiency and long service life.

- High cost performance and wide application range. Great value for money and adaptable to a variety of work environments.

- Using high-quality materials, low wear, high strength of the cutter body, and the process size is guaranteed to be qualified before leaving the factory.

- Precision manufacturing, sharp edge and firm welding. Using a single crystal diamond blade, the surface achieves a high-gloss effect.

- Durable and good machining accuracy.

Leveraging advanced technology in precision cutting we proudly present the Single Crystal Diamond Polishing Cutter – an innovation characterized by impressive durability coupled with outstanding efficiency levels. With an expansive range of applications meeting cost effective pricing points this tool is quickly becoming indispensable for work environments globally.

Our cutters performance advantages stem from top grade materials that deliver maximum strength while minimizing wear over time. Our streamlined manufacturing process ensures optimal sizing requirements before each product ships out from our factory floor – so you can expect consistent quality every time you order from us.

Using diamond robotic welding methods resulting in sharp edges make polishing tasks on various surfaces easy breezy while providing high gloss finishes as well – making it perfect for both large and small scale projects alike! The time for waiting is over. Take action and advance the level of your work by ordering today.

Products categories

Why Choose Us

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..