Side milling cutters provide a machining solution for milling machines to pare away material from the face of workpieces. These tools are securely mounted on the spindle, operating on the sidewalls of the material to be shaped.

From creating slots and grooves to crafting specialized shapes, the versatile side milling cutter is the ultimate tool for cutting pockets, gearing, and keyways in workpieces. Offered in a range of sizes and designs, this tool is a must-have for achieving top-notch precision.

A popular tool used for creating slots, grooves, and pockets in a workpiece is the circular side milling cutter. Resembling a wheel, it has a rim that serves as a blade and provides a consistent cut throughout the entire circumference. Ranging in size from small to large, this versatile tool can handle a wide variety of projects.

End Mills, the most widely seen type of side milling cutter, are capable of producing precisely-cut workpieces. Residing on the spindle of the milling machine, they are designed to slice through any type of material from the side.

A variety of sizes and types of end mills can be obtained, with the most typical being the ball end mill. Characterized by its rounded tip, this mill carving tool is used for cutting slots, precise grooves, and pockets on the surface of a workpiece.

A range of sizes can be found among ball end mills. Perhaps the most commonplace of these is the square end mill, boasting sharp corners well-suited to create pockets, grooves, and slots in any given material.

An array of sizes can be found in the realm of the square end mill. Amongst these, the most popular is the dovetail end mill with its pointed tip used for carving slots, grooves, and pockets in the material being worked.

A stunning selection of dovetail end mills awaits those seeking the perfect fit for their needs.

Related Product

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

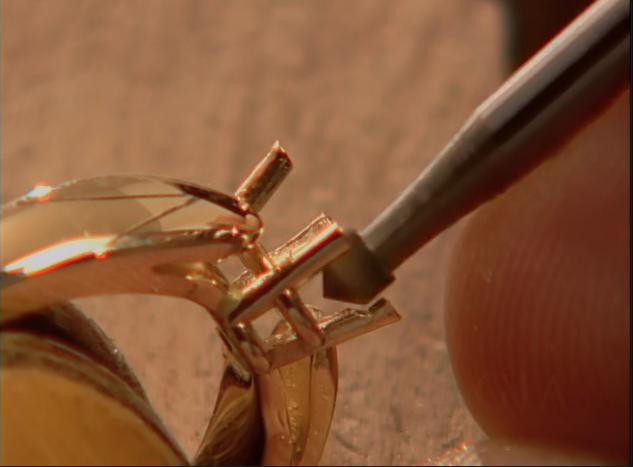

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Post time: 2023-07-06