An engraving process known as rotary engraving involves cutting intricate designs and patterns into hard surfaces, including metal, plastic, and wood. A rotating tool is used to delicately remove material from the surface of the engraving material, lending it a unique textural quality that can be both attractive and useful.

Throughout history, rotary engraving has been used as an artistic technique to create patterns and designs. The ancient Egyptians were the first to use a bow-shaped tool for this purpose, engraving intricate designs into stone. Nowadays, rotary engraving serves a variety of industrial and commercial purposes, making everything from custom signs to badges and plaques.

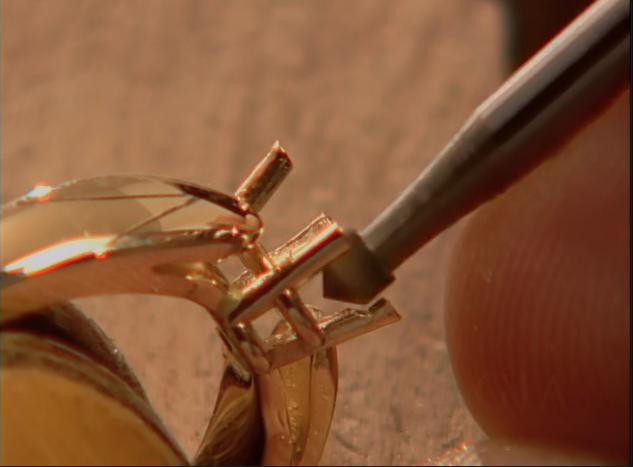

An electric motor powers the rotary engraving tools, equipped with a spindle that holds a tool bit in place. As the spindle moves across the surface at a fast rate, it expertly cuts into the material with adjustable width and depth based on the rate of speed and feed.

In order to successfully craft a lasting impression, one must be sure to secure the material firmly in place prior to wielding the rotary engraving device. Doing so will pave the path for precise and uniform markings. Moreover, it’s integral to opt the correct tool bit according to the material; various materials demand distinctive tool bits in order to deliver intended results.

With rotary engraving, a tool bit can be moved in virtually any direction, allowing for intricate designs and precise patterns to be brought to life. This advantageous method carries the added benefit of being both speedy and foolproof, enabling engravers to churn out superior work with ease and aplomb.

Rotary engraving makes it possible to craft stunning name plates, signs, badges, and trophies from a variety of materials. It’s a reliable method to inscribe serial numbers and other marking onto metal components. Moreover, it is incredibly versatile, capable of etching intricate decorative patterns onto jewelry and other items.

An array of engraving tools of diverse sizes and configurations are designed to perform on numerous materials, from metal to plastic to wood. For complicated engravings such as logos and illustrations, computer-controlled machines may be brought into play.

Rotary engraving is an ideal option for crafting elaborate details on diverse surfaces. Its rapid and reliable nature makes it perfect for creating captivating, resilient creations, regardless of the task. When armed with the right tools and a precise setup, rotary engraving can bring limitless possibilities to any artwork.

Engraving is an art form that activates the power of precision and permanence, rounding out its potential uses from customizing presents to producing labels and signage. Rotary engraving is a reliable and budget-friendly technique for carving designs or words into a material, utilizing a rotating metal tool known as a rotary engraver. With this process, creating intricate markings of unbeatable quality is quite achievable.

Durability and strength are key traits of the materials utilized in rotary engraving tools, with options ranging from solid carbide to high-speed steel. Particularly hard and capable of withstanding various temperatures as well as strenuous conditions, carbide is a popular choice although slightly pricier than their steel counterparts. Nevertheless, the somewhat less expensive high-speed steel tools can last longer in terms of sharpness, but need to be handled with extra caution as they may be less resistant to breakage and wear.

When looking to get an engraving done, it is important to be aware of the type and size of tool needed. Three of the main shapes available are round, square, and V-shaped. Generally speaking, the larger the engraving desired, the bigger the tool that should be chosen. Conversely, for a small image or logo, a smaller tool will do just fine.

The process of rotary engraving can be employed to design a plethora of materials – whether it be metal, plastic, or wood. To ensure that the material does not move during the procedure, it must be firmly affixed to the workbench. After it has been in place, an engraving tool is inserted into a swiftly rotating spindle, which whirls the cutting implement at a prodigious speed. As the spinning tool strikes the material, an intricate design or display of words will manifest on the surface.

The tool’s swiftness is directly proportional to the engraving depth. The rotary engraving instrument may be set to turn at a rate of 2,000 to 10,000 rotations per minute. A speedier motion generates more profound impressions, while slower rates create shallower markings.

Whether used for engraving awards, plaques, nameplates, and signs, or for etching serial numbers, barcodes, and logos onto products, rotary engraving tools offer an efficient and economical way to add a personal touch. Such tools can quickly produce intricate and highly precise engravings at a relatively low cost.

Handling with dexterity and precaution, rotary engraving tools are accessible to both the seasoned professionals and enthusiastic hobbyists. It is essential to take heed of their strength in order to avoid strain and harm.

Rotary engraving tools can produce long-lasting engravings with remarkable precision; these tools are cost-efficient and robust for a range of materials. Anything from detailed artwork to gently personalized words can be created with their practical application, leaving behind lasting effects on the objects engraved.

Related Product

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

Post time: 2023-07-25