For centuries, the wondrous art of gem cutting has been admired and practised. Diamond cutting, in particular, is a highly sought after and meticulous pursuit. Involving transforming a drab stone into a captivating example of jewelry, diamond cutting takes a great deal of talent and personal restraint. Many who take up the craft are entranced by its refinement and complexity.

Choosing the ideal diamond for cutting is the beginning of the process. Gem cutters take many factors into account when evaluating potential stones, such as size, shape, clarity, and the presence of any inclusions and imperfections. After settling on the right diamond, they will measure it accurately and then mark out where each facet must be cut out.

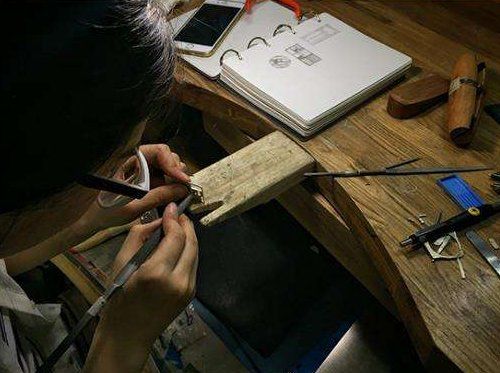

To manipulate the rock into its desired shape, the cutter will have to rely on a variety of tools such as saws, lathes, and burrs. As they gingerly carve on the diamond’s surface, they must be meticulous and zealous in cutting the diamond to perfection. Depending on the goal, the diamond may be manipulated into either a symmetrical round or a more intricate shape with several facets which must all be sized and contoured uniformly.

After the diamond has been shaped, a special polishing wheel spangled in a diamond powder spins around to give its facets an eye-catching sparkle. To make the diamond even more alluring, the cutter applies waxes and oils to draw out its innate beauty and brilliance.

After the diamond has gone through the process of being cut and refined, the precise jewels it is to be set on can be determined. From a golden or silver encasing to a necklace or bracelet, the diamond should be secured carefully and evenly in its new frame. The cutter must take extra caution to make sure the diamond is safely settled and balanced.

The creation of a radiant, polished diamond is a labor of love, demanding careful attention to detail, technical finesse, and meticulous effort. The long and difficult process can take hours, days, or even weeks of unwavering commitment to reach fruition. Yet in the end, the result of such refined artistry is a priceless gem that holds the promise of being treasured for years to come.

For countless centuries, gem cutters have dedicated themselves to transforming raw materials into exquisite works of art with outstanding beauty and value. This age-old craft of diamond cutting is something that will no doubt be admired and revered for centuries more.

For centuries, the artisans who skillfully manipulate raw gems into sparkling, magnificent jewels have been crafting them with the same unwavering process. Responsible for perfectly shaping, buffing and trimming the stones, gem cutters must be highly proficient in their trade to apply the intricate details required to craft diamonds. The exceptional results of their work are celebrated worldwide as the radiant treasures we are all so familiar with.

Once a diamond is expertly mined from the earth, a careful inspection of its quality, hue, and clarity is conducted. Afterward, the skillful gem cutter must decide how best to showcase the diamond’s beauty. This means determining which shape will be cut, what number of facets to employ, and how exactly to refine the diamond for an exquisite finished product.

Once the cut is chosen, the diamond is held securely in place, ready for the gem cutter to begin crafting it into a stunning masterpiece. Expertly using a set of diamond-tipped tools such as saws, grinders, and polishers, the cutter must delicately transform the diamond into its desired cut and shape while ensuring that every facet and edge is balanced and precise. The task of creating a diamond requires careful attention to detail and extreme accuracy in order to achieve perfect symmetry for every one of its facets.

Upon completion of the cutting and forming phases, a thorough inspection is conducted to assess the quality and crystal clarity of the diamond. Provided it passes a satisfactory level of scrutiny, the diamond is then cleaned, at which point it is ready to be fitted into a carefully designed metal setting; gold and silver are two popular choices used but various other metals can be employed as well. Regardless of the option chosen, a prong, bezel or other similar system must then be employed to firmly secure the diamond in place.

With expertise and precision, a gem cutter is capable of transforming raw gems into breathtaking works of art. This ancient craft, with a heritage that stretches back centuries, requires incredible attention to detail and a delicate hand. Every step of the diamond cutting process must be managed with care, from selecting the rough diamond to taking the finished product to its last phases of polishing. The result is an exquisitely crafted piece of jewelry, imbued with awe-inspiring beauty and value.

Related Product

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

Post time: 2023-08-21