Rebar Cutting Techniques Explored: A Comprehensive Guide to the Diamond Rebar Cutter

For reinforced concrete structures to be built safely and properly, the use of steel reinforcement (similarly referred to as ‘rebar’) is critical. To ensure the rebar is of a suitable length, diamond rebar cutters are used manually to efficiently cut through the steel, thus allowing for a proper installation. In the following passages, we will examine the features and benefits of diamond rebar cutters along with a comprehensive guide on how to use them.

Uncovering the Jeweled Power of a Diamond Rebar Cutter

Built for speed and precision, the diamond-studded rebar cutter is a handy tool capable of slicing through steel rods with ease. With a blade embedded with diamonds and a handle for managing the cutting process, the device delivers a swift and accurate cut, no matter the size and shape of the rebar.

Benefits of Using Diamond Rebar Cutters

Rebar-cutting tasks can be effortlessly achieved with the help of diamond rebar cutters that are endowed with many advantages.

Robust construction partners, diamond rebar cutters are built to withstand the challenge of the construction site. Compact and simple, these highly capable tools provide smooth steel rebar cutting aided by their lightweight design that can mould and adjust to all sizes and shapes of rebar.

Compared to manual tools, diamond rebar cutters are incredibly speedy and precise. They are able to effortlessly slice through steel rebar with accuracy and speed, letting you accomplish the task in no time.

Looking for an economical and accessible solution to cutting rebar? Diamond rebar cutters offer just that! With no need for electricity or servicing, these manual devices are low-maintenance and highly cost-effective. Here you have an option at your fingertips that is both affordable and easy to uphold!

Harness the Power of a Diamond Rebar Cutter

Accomplishing a job with a diamond rebar cutter can be a fairly straightforward endeavor, yet it is crucial to take safety precautions into consideration in order to guarantee the task is achieved accurately and with complete safety in mind.

For a successful cut, attach the rebar firmly in the cutting head via clamping or other applicable fastening mechanisms. Doing so will ensure the rebar’s stability and prevent it from shifting while being cut.

With the utmost importance, make positive that the cutting blade is firmly fastened to the grip. This precautionary step will guarantee that the hold does not slip while the steel bars are being cut, thus averting any potential harm or impairment to the rebar.

While using the rebar cutting tool, maintain a tight grip with both hands on the handle. This is essential to ensure a secure, successful cut without any unintentional slips or misalignments.

When slicing the rebar, a steady, even force should be utilized. Applying too much force can cause the cutting head to seize up, potentially leading to impairment of both the rebar and the cutting head.

For the task of cutting through steel rebar, diamond rebar cutters can be an optimal choice, boasting benefits that include efficacy, durability, and cost-effectiveness. However, using such a device to cut rebar also requires knowledge of appropriate safety measures. For example, it is essential to firmly secure the rebar and apply a steady force when using a diamond rebar cutter. By following such precautions and utilizing the proficiency of these cutters, it is possible to cut through steel rebar effectively and securely.

Achieve Professional-Level Rebar Cutting with the Diamond Rebar Cutter Manual.

Effortlessly cutting through rebar using a manual tool is now possible with the diamond rebar cutter. Despite the lack of electricity or other energy-sources to operate it, this revolutionary tool makes the chore of cutting rebar remarkably painless, fast, and convenient. Whether at the worksite or elsewhere, this incredible tool never fails to impress with its efficient cutting capabilities.

Crafted for optimal comfort, the diamond rebar cutter is an indispensable tool for efficient cutting. Boasting an adjustable handle and a diamond-coated steel wheel, it empowers users to make fast and precise cuts in rebar with no fuss. Furthermore, its flexible design permits precise adjustments to different rebar sizes, thereby enabling cuts of all lengths. Its ergonomic construction makes it a dependable companion for any task.

To utilize the diamond rebar cutter effortlessly, simply glide the cutting wheel along the whole rebar. The wheel should then glide in a slicing movement, skillfully perforating the rebar. Though convenient to use, this machine still calls for attention, as its blade is severely sharp. It is encouraged to wear protective accessories such as gloves and safety goggles when operating this tool.

Every construction or repair job involving rebar demands accuracy and efficiency, making a diamond rebar cutter indispensable. It can make light work of even the most challenging cutting tasks with ease, making it a go-to tool for anyone in the industry. Furthermore, its simple use and straightforward maintenance mean you won’t have to worry about wasting time using it.

After each utilization of the diamond rebar cutter, it is essential to clean the cutting wheel to prevent the accumulation of debris and dirt. Furthermore, it is necessary to sharpen the wheel regularly to guarantee that it performs optimally. Additionally, inspectors should assess the cutting wheel for any indications of damage or tarnishing, as these may impair effectiveness.

Any rebar workers should be certain to have one of these diamond-blade cutters on hand; it is one of the most convenient tools for quick and reliable rebar cutting. The tool is made to be easy to maintain, so with a bit of attention it will deliver years of results on the job. For any project involving rebar, this cutter will help in getting the job done faster and more efficiently than ever before.

Related Product

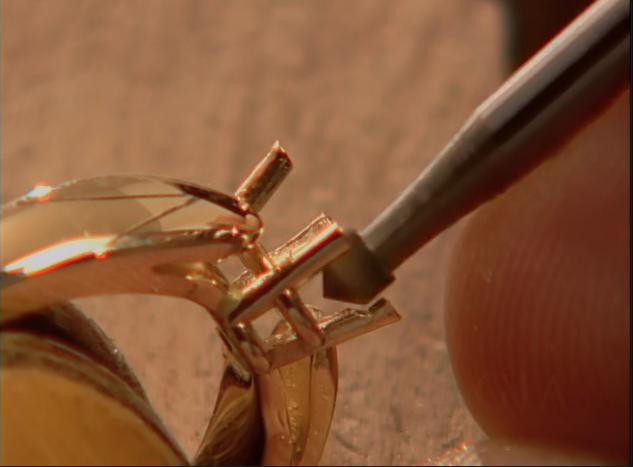

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Post time: 2023-08-15