A diamond disk cutter is an irreplaceable tool in the modern diamond cutting industry, one that has become indispensable in the production of diamonds, gemstones, and ornamental items used for jewelry. In this article, you’ll learn the basics: what a diamond disk cutter is, how it operates, and why it’s so widely utilized.

An amazing device capable of shaping diamonds and other treasured jewels, the diamond disk cutter is composed of two remarkable circular disks crafted from diamond that spin at dizzying speeds. Affixed to a sturdy frame and powered by an electric motor, this tool carves into the diamond with nuanced precision – a true testament to human ingenuity.

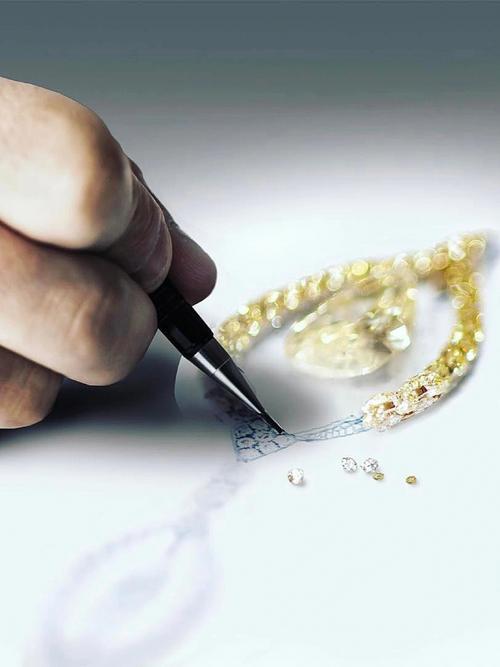

To fashion the angular shapes of diamonds, a diamond disk cutter is the contraption of choice. It couples a diamond bit tightly onto its swiftly rotating disks which is crafted to perforate the gemstone’s molecular structure with remarkable precision. This technique enables it to translate a multitude of figures into diamond – from rounds to squares to ovals.

The diamond disk cutter is greatly valued in the diamond cutting sector due to its two main attributes. First and foremost, it boasts exceptional precision and consistency when cutting; as it utilizes a diamond bit, the cut is invariably perfect on both sides, thus providing uniformity in terms of size and shape when crafting jewelry or any other decorative articles.

The diamond disk cutter provides excellent precision when altering the size and form of a diamond. Its variable speed and pressure let users customize the stone to artistic perfection, resulting in a product that looks attractive and can be sold for a higher price. Thus, it holds special appeal for jewelry-makers, who recognize the importance of getting the size, shape, and look of the diamond exactly right.

The diamond disk cutter has become a cornerstone of the diamond cutting domain, renowned for offering exceptional accuracy and control. It permits the formation of intricate designs and shapes, as well as generating uniform pieces with relative ease. Furthermore, it has drastically reduced the labour and time involved in cutting and forming diamonds, making it a significant asset within the diamond cutting sector.

If you need accurate and efficient cuts through a range of materials, diamond disk cutters are an ideal solution. They can cleanly slice through stone, ceramic, tile, and even metal! These versatile tools make exact cuts with a minimum of effort.

The diamond disk cutter is a powerful tool that allows users to cut through a variety of materials with the aid of diamond-edged disks. This power tool is designed with a handle, which provides users the ability to adjust the speed of the motor and steer the direction of the cut. Depending on the task at hand, this device can run on either electricity or battery power. Additionally, a metal cup holds the diamond disc in place during operation.

A formidable combination of embedded diamonds and hardened metal or ceramic make up the diamond disk, the essential element of a diamond disk cutter. Encased in this structure is a pivotal center core granting the disk its movement capability, yet it’s those hidden diamonds that ultimately permit the machine to conquer even the most difficult materials.

When utilizing a diamond disk cutter, it’s essential that the right disk is chosen for the material being cut. An incorrect disk may not achieve the desired results, or – more importantly – cause injury due to the device’s rapid rotation. All safety equipment should be on hand and operational in order to conduct cutting operations safely and with confidence.

When the diamond disk is ready and in place, it is time to power up the motor and embark on a very precise cutting journey. As the diamond disk slowly but surely grinds away at the material, a number of passes may be required before the desired piece is reached. Although this process is relatively laborious, the accuracy of the results make it absolutely worth it.

For precise cuts on tough materials, the diamond disk cutter is unbeatable. Taking advantage of the power of diamond disks, it is able to offer quick and effortless slicing through otherwise demanding materials. Plus, its affordability makes it a great choice for tackling any project without having to break the bank.

If you’re searching for an effective tool for making perfect, precise cuts in a range of materials, then a diamond disk cutter should be your go-to choice. With diamond disks providing formidable cutting capabilities, tackling tougher materials will be stress-free. On top of that, the affordable cost of diamond disk cutters makes them an ideal selection for those looking for an efficient option that won’t break the bank. So, when you need a reliable diamond disk cutter, don’t wait – get one!

Related Product

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

Post time: 2023-07-13