A new, inventive tool that is helping to advance the construction and manufacturing sectors is diamond-coated cutter wire. The materials it comprises of – diamond and nickel-plated steel – create a unique cutting edge that can slice through a variety of sturdy materials, including steel, aluminum, and other metals. When employed solely for construction or to produce shapes, its incomparable durability yields accurate and precise cuts. Diamond coating offers utmost longevity as well as making it the perfect choice for intensive slicing activity.

Instead of relying on conventional cutting tools, we can now utilize diamond coated cutter wire for precise and accurate cutting. Taking a fraction of the time, this handy tool is renowned for its extraordinary capability to cut through hardness quickly and effortlessly, providing a polished finish to the cut surface due to its diamond coating.

The diamond coated cutter wire may be obtained in a variety of sizes, from a petty 0.010 inches to a generous 0.120 inches in diameter. This extensive variety of dimensions makes it exquisitely usable to incise intricate shapes and complex sculptures. Moreover, its diamond-coated sheath renders it highly resilient against abrasions and ensures that it can be wielded on multiple metals such as steel, aluminum, brass, and copper.

Working with a diamond-coated cutter wire is hardly rocket science! Its simplicity makes it a breeze to use, both in manual and machine-assisted operations. All you need are a cutting surface – think table or bench – along with a cutting attachment such as a die grinder or milling machine. Once all has been set up, just attach the diamond-coated cutter, and slice right through the material!

With its diamond coating, the cutter wire is resilient and can make intricate and accurate cuts. It is much more efficient than conventional cutting tools and can be applied to many types of materials, making it a perfect option for the building and manufacturing industries.

Anyone in search of a cost-effective way to do the job properly can find solace in a diamond coated cutter wire. Such cutting tools are financially viable compared to conventional ones, all while having the ability to bridge a variety of materials with ease. Saving money with unparalleled efficiency has never been easier!

With its diamond coating, the cutter wire is leading the industry in terms of efficient material-cutting. A precise, robust tool that is faster than conventional methods, it provides great value for money. The versatile nature of this tool makes it a great option for anyone in the need of a trustworthy slicing device.

How Does a Diamond-Coated Cutter Wire Work?

A specialized tool used to slice many different materials, diamond coated cutter wire is a thin, stainless steel wire coated with diamond particles that can provide immense cutting power. When the wire is spun by its motorized spindle at a high velocity, it creates friction that is transferred to whatever material is being worked with. The diamond particles act like a fine abrasive and cut away the material as if slicing through butter.

Crafted with diamond-infused particles, the cutter wire offers a powerful solution capable of slicing through even the hardest of materials. From steel to titanium, and from wood to rubber, few can stand up to its seemingly limitless might. The molecular structure of hardy materials like stainless steel falls effortlessly to its blade, while soft substances like foam and plastics yield effortlessly in its wake. Versatile in nature, the diamond coated cutter wire is a tool like no other.

Glimmering Gains of Diamond Coated Cutter Wire

One of the myriad advantages of diamond-coated cutter wires is that they provide a wealth of benefits, such as:

Cutting with diamond particles embedded in the wire ensures that even the most intricate shapes can be achieved with pinpoint accuracy.

With its speedy spinning capabilities, the wire is the ideal tool for large-scale projects or those requiring prompt completion. This facilitates fast cutting times and superior results.

With its coating of diamond particles, this electrical wire can persevere through multiple tasks, providing a lasting, durable presence.

4. Adaptability: The wire is a remarkable tool, capable of slicing through a spectrum of materials, being just the right choice for multiple tasks.

Over time, using the diamond-coated cutter wire proves to be economical, allowing considerable savings when compared to other cutting tools.

Utilizing Diamond-Coated Cutter Wire: A Comprehensive Guide

The ubiquity of diamond coated cutter wire is seen in many industries, including but not limited to:

For automotive projects, this tool is essential, allowing it to effortlessly slice through metals and other substances commonly found in cars.

2. Aerospace: Wire cutting is a vital part of aircraft production, and this wire is used to cut through aluminum and other essential components of these airborne vessels.

The wire is indispensable for the production of electrical components as it not only enables the cutting through of copper but also other related materials.

The tool is designed to effortlessly slice through the medical-grade plastic and other materials that are employed for medicinal purposes.

For use in construction, wire enables cutting through materials such as metal to build structures with precision and ease.

The diamond powder-coated cutting wire is an efficient and economical solution when it comes to slicing through different types of material. This tool boasts the power to quickly split through material such as steel, titanium and stainless steel, proving it to be an incredibly advantageous asset in a variety of industries, including automotive, aerospace, electrical, medical and construction. Its versatile nature renders it incomparable to other cutting solutions in terms of both cost-effectiveness and effectiveness.

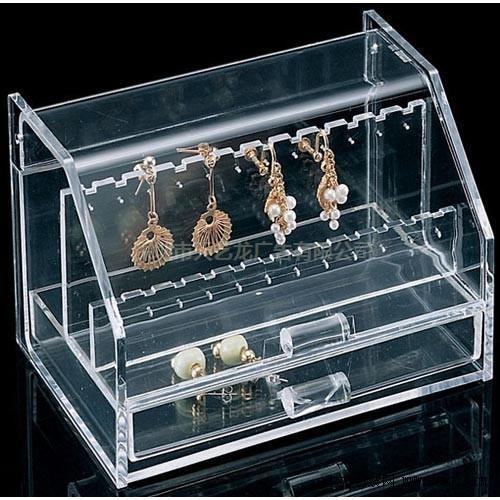

Related Product

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

Post time: 2023-08-15