In the realm of material cutting and fabrication, diamond and glass cutters are two iconic tools that have served the manufacturing process for centuries. What sets them apart? In this article, we unravel their differences, the materials they cater to, and why these tools are so integral.

For activities such as cutting and shaping, diamond cutters are an ideal choice due to the unique properties of the material they are crafted from: Diamond. This remarkable gem is formed of carbon atoms, making it the cutting edge of properties in terms of hardness. With diamond cutters, a variety of materials can be slashed through with ease, ranging from metals and stone to glass and even ceramic.

For the purpose of precise cutting and shaping, artisanal glasscutters are often crafted using quartz. This resilient silicate mineral holds strong and is consequently ideal for intricate designs in glass – essential for the creation of stained window art and bespoke lamps.

Diamond cutters stand out from their glass counterparts in terms of their ability to master materials that are more resistanct and hard. From glass and ceramic to materials that are considered unsuitable for glass cutters, diamond cutters possess the required level of fortitude and hardness – allowing them to shatter through what would prove inhibitory to the ordinary glass cutter. Conversely, glass cutters lack the strength required to tackle tougher materials, leaving them as the chiefly viable solution for softer materials including glass and ceramic.

Man-made goods require the precise use of both diamond and glass cutting tools. These strategic instruments assist in the forming of various wares, like jewelry and construction materials, by slicing through a range of materials that vary in hardness. Harder substances, such as metals and stone, are best managed with a diamond cutter, while softer substances like glass and ceramic find their cleavage best realized by a glass cutter. The production process is adroitly aided through the use of these two essential tools.

From creating delicate jewelry to crafting intricate glass designs, diamond and glass cutters form a key part of multiple industries. To construct projects made from hard materials such as metal and stone, these sharp tools are essential. Jewelry manufacturers in particular rely on diamond cutters for cutting and sculpting various precious metals and stones. Meanwhile in the glass-making industry, glass cutters are valued for producing attractive patterns and shapes. Clearly, diamond and glass cutters are indispensable tools across many sectors.

Cutters for diamond and glass are integral components for the fabrication of any number of materials. As tools that expertly slice through both hard and soft materials, these dynamic cutters have been respected throughout time, and are essential to producing a diverse selection of products. It is due to the mighty cutter, be it diamond or glass, that industry is able to make great leaps forward and demonstrate true quality in its output.

Crafting projects require precision and accuracy – a fact that is brought to the surface with the diverse and specialized range of diamond and glass cutters available. From tiles to stones, glass to metals, these cutters provide the necessary shape and size for a plethora of construction and DIY tasks.

For those tricky precision-cutting projects, diamond cutters are the way to go. These powerful tools, made from diamond-tipped blades, make slicing through thick materials like glass, tile, stone, and metal an easy feat. With a range of shapes and sizes on offer, there’s a diamond cutter to fit any task. Whether you’re cutting paver stones or that tricky ceramic tile job- there’s a diamond cutter to get the job done right.

Tungsten Carbide-made glass cutters are an essential tool for any project involving glass. From manual cutters used for scoring glass surfaces to electric ones used for precise slicing, they come in different sizes and styles to suit various needs, making them perfect for cutting windows and doors. With the ability to create neat incisions in the hardest of glasses, they are at the very top of a craftsperson’s glazing toolbox.

If you are in the market for a diamond or glass cutter, it is crucial to consider your purpose. Diamond tools are often used for detailed and precise slicing, whereas rely on glass cutters for when you need to slice through glass. Additionally, the size and shape of the object you are cutting will help you figure out the most suitable cutter for your task.

To successfully utilize a diamond or glass cutter, protective gear is non-negotiable. Safety glasses, gloves and appropriate clothing should all be worn when using the cutter. Furthermore, a dust mask should be utilized to avoid any hazardous inhalation of the by-products of the cutting process. As an added precaution, it is essential to keep the surrounding space free of any debris for optimal safety and results.

Ultimately, both glass cutters and diamond tools are crucial to the completion of a variety of construction and DIY projects. With so many sizes and varieties available, it is important to ensure that you select the appropriate tool for your specific project. Bear in mind the size and shape of the material you’ll be working with, as well as mandatory safety gear that should always be worn when using either type of cutter.

Related Product

MCD Polishing Cutter for Gold Silver

Product Information Origin Tianjing, China Whether To Coat Uncoated Brand MSK Unit Weight 0.3kg Tool material Tungsten steel bar imported from Germany Product Size Shank Dia […]

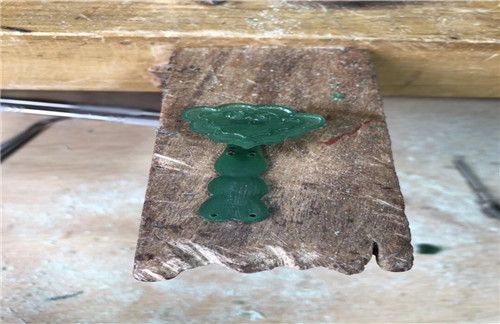

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

Parameter Product Name Single Crystal Diamond Carving Cutter Rotating Speed 10000-30000r/min Tool Nose Width 0.1-6.0mm Feed 1500-5000mm/min Blade Material Single Crystal Dia […]

MCD High Gloss Chamfer Cutter For Gold

Product Information Origin Tianjing, China Type Flat Milling Cutter Brand Msk Whether To Coat Uncoated Series Cutter Milling Cutter Processing Range Clocks And Watches, Copp […]

Lathe Bits MCD High Gloss Chamfer Tool

Product Information Origin Tianjing, China Cutting Edge Form Straight Edge Brand MSK Material Single Crystal Diamond Chamfer Angle 30°-180° Type Angle Milling Cutter Minimum […]

MCD Turning Tool Mirrow Finish R Cutter

Product Information Product Name Single Crystal Diamond Lower Chamfering Inner R Cutter Brand MSK Handle Material Tungsten Steel Blade Material Customized Pcd, Single Crysta […]

Diamond Turning Tools Outer Jewelry R Cutter

Product Information Origin Tianjing, China Material Tungsten Steel Brand Msk Type Half Round Key Milling Cutter Product Name Single Crystal Diamond Side Edge Arc Milling Cut […]

Single Crystal Diamond Polishing Cutter

Origin Tianjing, China Shank Diameter 6 (mm) Brand MSK Blade Change Method The Diamond Is Welded To The Cutter Body As A Whole Material Single Crystal Diamond (MCD) Scope Of […]

Post time: 2023-08-20