Welcome To MSK

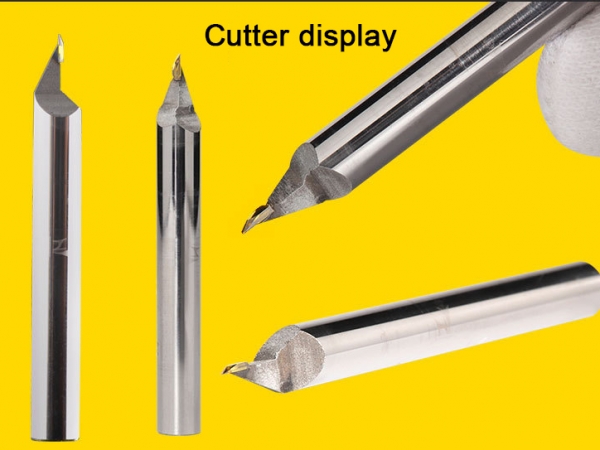

CVD/PVD/MCD Gold Jewelry Diamond Engraving Cutter

| Parameter | |||

| Product Name | Single Crystal Diamond Carving Cutter | Rotating Speed | 10000-30000r/min |

| Tool Nose Width | 0.1-6.0mm | Feed | 1500-5000mm/min |

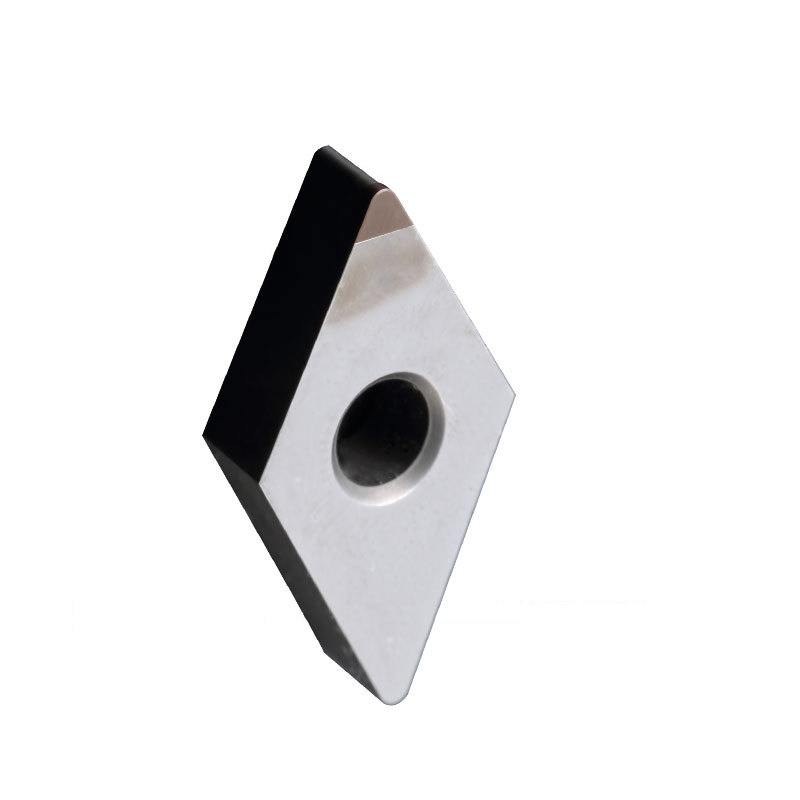

| Blade Material | Single Crystal Diamonds, Customizable Natural Diamonds, CVD, PCD | Application Equipment | CNC And Other Machining Center Equipment |

| Handle Material | Tungsten Steel | Processing Material | It Is Mainly Used For The Processing Of Various Non-Ferrous Metal Materials Such As Gold, Silver, Copper, Aluminum And Alloys. |

Feature:

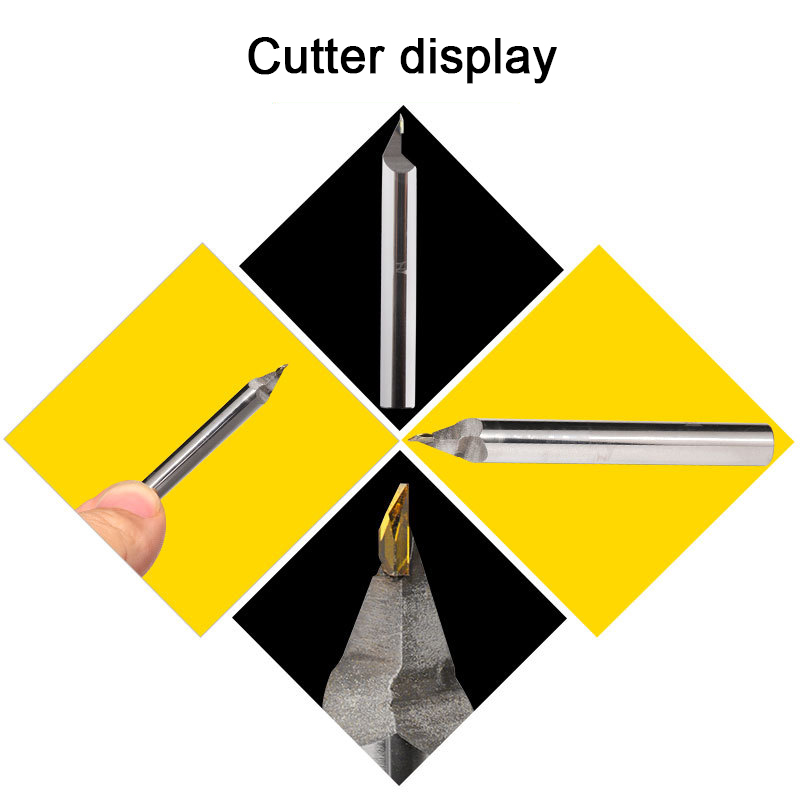

- It is mainly used to engrave jewelry patterns, and the surface of the engraved lines has a high-gloss, high-brightness reflective surface.

- The tool parameters can be customized freely, the width of the engraving line is 0.1-6.0mm, the common range is 0.1-1.0mm, and the width of the diamond is within 3mm.

- The carved line is a continuous unbroken facet. According to the programmed engraving effect, various characters, patterns and other colors can be engraved. Strong stability, high finish, smooth cutting, reduce cutting resistance, improve processing efficiency and tool life.

- Using single crystal diamond material, high hardness, high sharpness, high wear resistance, high cost performance.

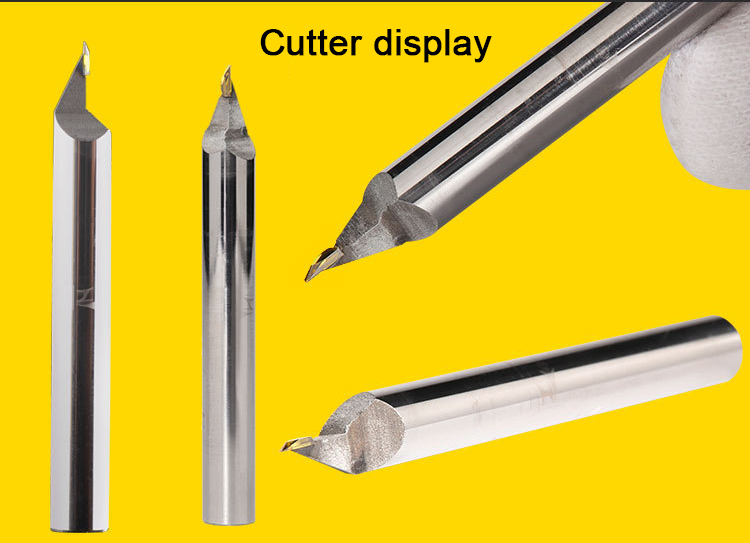

Tool parameter analysis:

front corner

The positive rake angle is large and the cutting edge is sharp. For every 1° increase in the positive rake angle, the cutting power decreases by 19%. The positive rake angle is large, the edge strength is reduced, the cutting edge is relatively fragile, and it is easy to wear and break. The negative rake angle increases and the cutting force increases, which is suitable for cutting high-strength workpiece materials.

rear corner

The clearance angle is large, and the flank wear is small. The larger the relief angle, the lower the strength of the cutting edge. The small relief angle is suitable for workpiece materials with high strength mechanical properties. The large relief angle is suitable for softer or low-strength workpiece materials.

Precautions

Do not touch the cutter head with your fingers or anything. Although the hardness of diamond is very high, even a slight touch will damage the cutting edge and make the cutter unusable. Because a hard particle or even dust hitting the blade at high speed is enough to damage the blade.

If there is wear during use, it can be detected by microscope. If it is within the scope of grinding, it can be re-ground and reused for many times to save costs. If it exceeds the range of measurable wear, the tool needs to be replaced.

The use and maintenance of single crystal diamond tools

- The single crystal diamond tool is brittle, and the blade is very sharp, and it is prone to chipping when it is impacted.

Use under vibration-free working conditions: At the same time, the rigidity of the workpiece and tool and the rigidity of the entire system should be improved as much as possible.

its vibration resistance. The cutting amount below 0.05mm is suitable.

- Higher cutting speed can reduce the cutting force, while low-speed cutting will increase the cutting force, thereby accelerating the tool chipping failure, so

The cutting speed should not be too low when using single crystal diamond tools.

- The single crystal diamond tool should be avoided in contact with the workpiece or other hard objects in a static state to prevent bumping the cutting edge of the tool and avoid

Avoid stopping the tool without leaving the workpiece during cutting.

- The blade of the diamond cutteris easily damaged. When the blade is not working, protect the blade with a rubber or plastic cap and place it in a separate place.

Keep it in the cutter box, wipe the blade part with alcohol before each use, and then work.

- The detection of single crystal diamond tools should use non-contact measurement methods such as optical instruments, and use light as much as possible during inspection and installation.

When testing the installation angle, use a copper gasket or plastic product to place it between the tool and the testing instrument to prevent the blade from being touched.

damage and increase tool life.

- Environment (dust particles: dry humidity, etc.): the stability of machine performance; the operating proficiency of personnel, etc. have an impact on the life of the tool.

Do you crave precision engraving for your intricate jewelry designs?

Look no further because our latest innovation has got you covered The Jewelry Diamond Engraving Cutter! This is the tool for you if you’re a jewelry maker or artisan with an eye for detail.

Our versatile cutter caters to users’ various needs by providing customized tool parameters making it easier than ever before to achieve desired results in a range of line widths between 0.1mm 6mm with the most commonly used widths being between 0.1mm 1mm whilst diamond width can reach upto3mm. The jewel in this products crown is its smoothness due to its high gloss reflective surface which provides unbroken facets resulting in stunning flawless finishes perfect for bespoke high end luxury jewelry making! The Jewelry Diamond Engraving Cutter boasts many benefits including unparalleled stability.

Its robust build quality enables it to operate flawlessly over prolonged periods of time with continuous use. This feature saves users both time and money while also increasing productivity levels. Additionally the tools design allows users to unlock their full creative potential by crafting intricate patterns with precision accuracy using various colors.

The engraved effect produced by this cutter is customizable allowing for unique designs without any flaws or errors in the final product giving users the confidence they need when investing in this must have tool. In conclusion every artisan involved in jewelry making requires a reliable tool capable of producing detailed work with ease while increasing productivity levels at minimal costs – making The Jewelry Diamond Engraving Cutter an invaluable investment.